13. EXPECTED BATTERY LIFE & CELL CYCLE RATING

by Blue Heron Tech Support Team

Lithium cell cycle rating and how that should be used is not well understood by the general public. This paper lays out some of the facts in this area and provides suggestions on how this information should be used in purchase decisions by consumers, specialists such as engineers and installers, and hopefully by those doing pseudo-market testing (e.g., so-called battery teardowns) of lithium batteries.

PART 1 - CELL CYCLE RATING : WHAT IT IS --

What is Cycle Rating?

Cycle Rating refers to the number of defined full charge and discharge cycles a cell is able to provide before it drops to a certain level of residual capacity. A cell manufacturer subjects a sample set of cells from a production run to a set of cycle charge and discharge cycles under standardized conditions, for example a constant charge and discharge load of 0.5C pulling the cell down to 20% SoC (80% Depth of Discharge – DoD), at 21°C, until the cell has only 80% residual capacity. These cycles are done continually, with a specified rest between half-cycles. This provides relative data designers can use in selecting appropriate cells for their application’s needs.

What Does it Mean and Not Mean?

As noted this provides the relative capabilities of one cell vs. others. It is not a predictor of expected battery life, as actual life will be dependent on actual use conditions and cell calendar life as noted later. In testing the cells are standing by themselves on a test device shelf with clear air around them. In actual use cells are usually stacked closely together, and in some form of battery case. These post-test configurations restrict heat rejection. Also, ambient conditions could be much higher and lower than the standardized test temperatures, and research has shown that temperatures higher or lower than the test conditions are a significant contributor to shorter cell life than the cell rating.

In short, cell cycle rating is a relative measure to compare across cells. It is not a predictor and should not be used as a predictor on specific cycles one will experience in actual use. A battery made from high cycle-rated cells will last substantially longer than one made with cells of a lower cycle-rating. [1]

Why do Cells From Different Manufacturers or Different Models Have Different Cycle Rating?

The factors that affect cell cycle life are several. In many cases these improvements in cell cycle life have occurred over time, as the technology has improved in materials and electrolytes. There are too many to detail here. But as an example, one area of change has been in the so-called slitting methods to cut the large rolls of cathode and anode material into the smaller sheets that are rolled up with separator material in making the cells. The early cutting was done by standard industry cutting machines. The fineness of that cut was not great and left “hairs” or strands that contribute to self-discharge in the cell. Early cells had higher self-discharge ratings and greater resistance to charging and discharging because of this effect, and had cell cycle ratings of 1,000 and 2,000 cycles. As mechanical cutting tools and research specific to the lithium electrode materials were developed, in conjunction with improved electrolytes, higher cell cycle ratings have been achieved. And further developments in this technology have further improved the fineness of the slitting process and contributed to even higher cell cycle rating in recent years. (See example slitting machine at the end of this paper.)

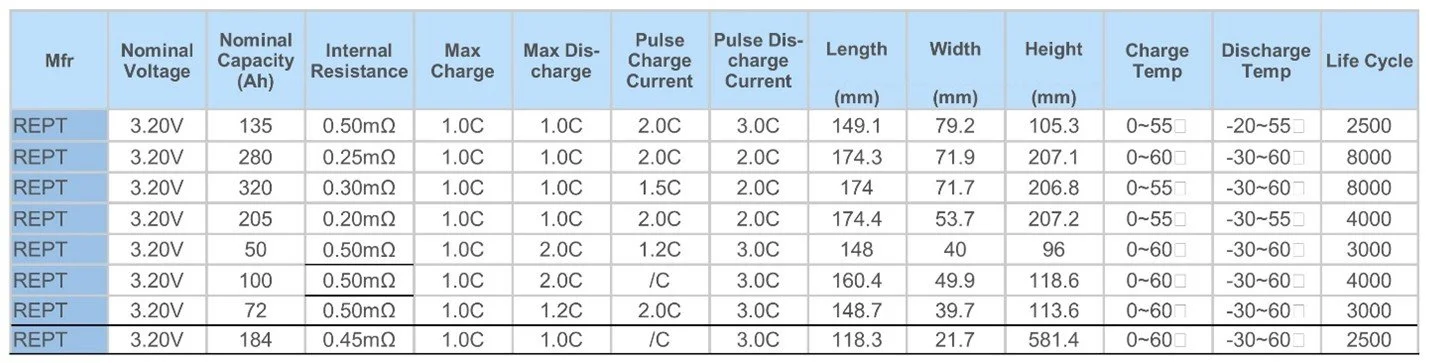

Another example of improvement over time is the enhancement in processes to apply graphite to the anode. But, even as processes have improved producing the high-end cells, older production lines stay in operation, because there is a demand for the shorter cycle-life and cheaper cells that can be produced on these older production lines. So, one can find today, cells that are rated per the cycle rating standard at 1000 cycles, and cells up to 10000 cycles, and even wide ranges across a single manufacturer, due to age of production lines and advances in technology. Note the example below of REPT cells, with models of 2500 rated cycles, up to 8000 cycles. This illustrates a wide range of quality levels in cells from just one manufacturer. So, labelling one cell manufacturer as a high quality one and another as low quality, is inaccurate. Designers should pay attention to cell specs for what is appropriate to their application.

Specs for RPT Brand Cells - (Note Range of Cycle Rating Across Their Lineup of Cells)

(Above table is excerpted from the Chinese Institute of Manufacture’s database, available to registered manufacturers.)

PART 2 - CYCLE RATING VS. GRADE A : FINDING ACCURATE CYCLE RATING --

How Does Cycle Life Relate to Grade A?

Grade A simply means the cell meets the manufacturer’s quality and safety specifications of the cell. One can find Grade A cells at all of the cycle rating levels noted above. Grade A is not a uniform level of quality. One really needs to look for Grade A cells that are at the cycle rating level or expected calendar life appropriate for their application. Higher quality cells have a higher cycle rating. Often the selection is a value decision, discussed further, below.

Where are the Requirements for Cycle Rating Stated?

There is no consensus standard in the US, but there is in China. And as that Chinese standard seems to be objectively developed, it has served the industry well. But, it is not widely known outside of Engineering circles, who have used the criteria established in that standard for many years. That Chinese Standard is GB/T 31484-2015. In this standard it specifies:

(1) For “traction batteries” (i.e., electric vehicles, or EV, applications) cells shall be tested at 1C charge and discharge levels, to 100% DoD, with 80% residual capacity remaining to establish cycle rating, rounded down. (Note that EV’s are rarely charged or discharged at 1C, often experiencing charge and discharge rates of 2C to 3C, and at higher temperatures. Active cooling is required to support charge and discharge at 2C or 3C. In practice, because of these high charge and discharge rates, these cells often see only 3 to 5 years of life, even with liquid cooling and rated at 8000 cycles. More on expected cycle and calendar life is discussed below.)

(2) For “other applications” (frequently referred to as ESS or energy storage systems). Lithium applications on boats and RV’s often fall into this category, storing energy for moderate to low discharge rates by electrical systems. The standard states cells for these other applications shall be tested at 0.5C charge and discharge levels, to 80% DoD, with 80% residual capacity remaining, to establish cycle rating.

That standard also defines other details of the standardized testing, such as number of samples per production run, standard testing temperatures, rest periods between charge and discharge periods, and other test parameters like temperature and humidity.

Where is Cell Cycle Rating Reliably Stated?

Cell cycle rating is required to be done by the cell manufacturer. These are large companies that are listed companies (on one of the Chinese stock exchanges), and are not producers of the volume of batteries one sees on Temu or Amazon. The results of cell manufacturer cycle testing are documented in their Cell Specification. This is a separate document of between 10 to 20 pages, typically. And can usually only be obtained from the cell manufacturer or the cell distributor one buys the new cells from. The myriad of traders that sell cells on Alibaba and AliExpress do not have and usually don’t distribute these specifications. I have heard one YouTube evaluator refer to cell manufacturer cell specification documents as being held as if they were state secrets, and he is correct.

The companies selling the cheap batteries on Temu and Amazon do not want you to see these cell manufacturer specifications, to be able to check on their inflated cycle rating claims. Or to have the data to check if the cells they built their batteries from might be recycled or reject (Grade B) cells. The places you cannot trust cycle rating are in the sales documents, webpages and battery stickers of the cheap battery manufacturers. We have found this in every instance we check.

So, for the general public getting access to those cell specification documents is very difficult. As a battery manufacturer, we demand copies of those cell manufacturer specification documents so we have confidence in the quality and expected life of the lithium cells we use. Before buying a battery, ask the selling company for a copy of the cell manufacturer’s specification document. YouTube evaluators should obtain the cell manufacturers specification, so they understand the true cycle rating of the cells in the battery they are evaluating. Compare the cell manufacturer’s cycle rating based on testing to the claimed rating by the battery manufacturer. Don’t accept a short, one-page so-called specification table from the battery manufacturer; that can’t be trusted. The battery manufacturer should be able to get that detailed cell manufacturer’s specification for you.

PART 3 - BATTERY CYCLE RATING

How Should Cell Cycle Rating Translate to Battery Cycle Rating?

Battery manufacturers in the industry should state their battery cycle rating as no more than that of their cells, based on the standards noted above for ESS applications. Some give ratings based on only partial discharges; those are not relevant. Also verbal claims aren’t acceptable. Ask for the cell specification document by the cell manufacturer that is 10-20 pages or longer; that way you know you are getting the right information. It is improper to claim a cycle rating for the cells used that is higher than that demonstrated in the cell cycle testing. Any reference to a cycle rating associated with a battery, really means the cycle rating of the cells used in that battery. US battery manufacturers are generally more truthful in stating their cell cycle rating, as they can face truth-in-advertising lawsuits. The Chinese battery companies do not face that risk in their home judicial system; factual accuracy in advertising is at the buyer’s risk. It is considered the buyers’ responsibility to ensure a product will meet their needs.

Does Cycle Rating Predict Battery Longevity?

In short, the answer is no. One should not try to correlate the cycle rating to something like the number of days a battery will last. As noted earlier, the battery configuration and the operating environment may present a more challenging operating environment than occurred in the standardized cycle rating testing. So, batteries usually do not see the number of rated cycles in practice as the cells demonstrated in the cycle rating tests. (See notes below on approximate calendar life for different cycle ratings.)

Effect of Cell Cycle Rating on Battery Cost?

Cycle rating definitely affects cell pricing. Often the cost of a battery with Grade A cells rated for 3000 cycles is much lower than that of a battery with 6000 cycle rate cells. But, that is if you can find the true cell cycle rating. Too often the battery manufacturer hides the true rating, or blurs it by claiming a lot higher number, with a footnote that says the rating is based on 40% depth of discharge cycles. That is dishonest as they are not using the cycle rating standard correctly and are counting a partial cycle as a full cycle.

The economics are simple. For a battery that is at a substantially lower cost than another, if both have Grade A cells, it usually means the cells of the high-cost battery are a higher cycle rating, and the battery itself is thus a higher quality battery, will have greater reliability in operation, and will have a much longer life. [2]

PART 4 - BATTERY AND CELL CALENDAR LIFE

What is Calendar Life, and is that Important?

Calendar Life is the general term that relates to the expected life of the battery. It reflects how long a cell, and thus the battery it is in, will last. There are other chemical processes that occur in a lithium cell that are more related to time and contribute to reaching end of life in the cell, no matter the number of cycles.

One example is the formation of the SEI layer. That layer is beneficial in that it has the Li-ions lined up and ready to do their electron transfer function, supporting greater rates of charging or discharging, than if the layer didn’t exist and ions were equally distributed through the electrolyte solution. But that layer can be detrimental in terms of continued increase in density over time, reducing the electron transfer rate and increasing the internal resistance of the cell. An increase in IR leads to reduction in the electron transfer rate and also adds to rise in temperature of the electrolyte and electrodes. This process occurs over time, and is not as highly dependent on cycle count.

From research and practical applications, we find that calendar life is shorter for cells with a low cycle rating, and much longer for cells with a high cycle rating. High cycle rated cells employ advancements in cathode and anode structure and in electrolyte formulation, which lead to a higher cycle rating, and a corresponding longer calendar life. Research has found that LiFePO4 cells that have a high cycle life rating generally also have a longer calendar life if not abused. [3]

Calendar life is very important as it may be more relevant to the life the batteries achieve, as opposed to an actual cycle count. And the calendar life of a battery can be reduced or extended depending on how aggressively or lightly the battery is used. [4]

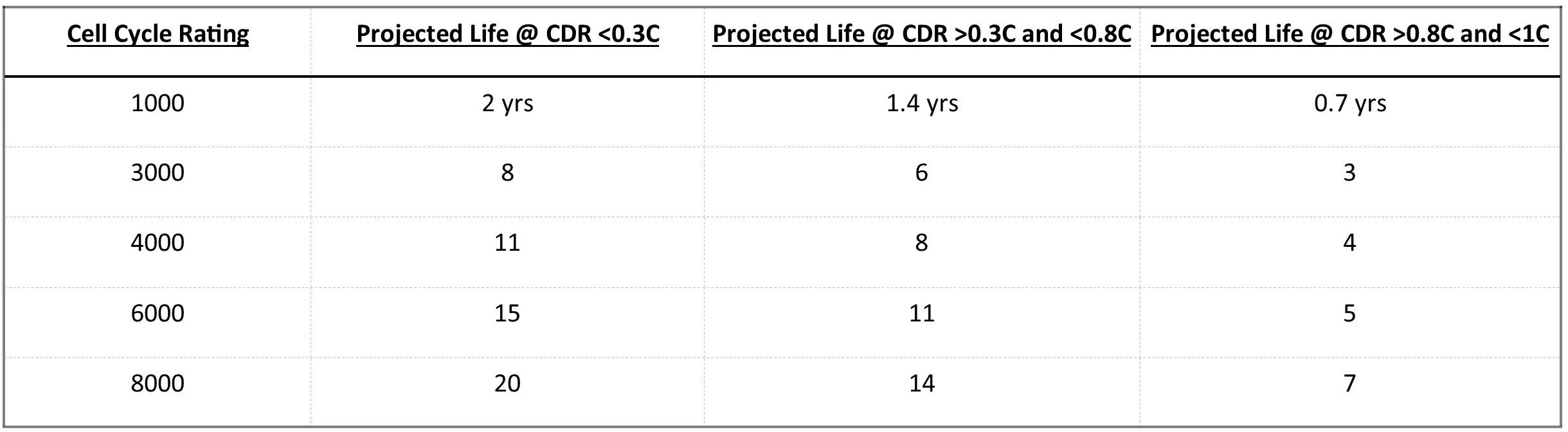

Based on actual personal practice of using cells in marine and RV applications, we provide below an expected calendar life for cells of different cycle rating, under different use conditions.

PART 5 - EXPECTED LIFE : CALENDAR LIFE --

What Sort of Calendar Life Can I Expect for my Battery?

In brief, as discussed earlier, a higher cycle rated cell will have a longer calendar life, calendar life can be affected by high-vs. low charge and discharge rates, and calendar life is not exactly measured, so consensus on a ballpark level is useful. The table below is based on the experience of an engineer and sailor who cruised for over 25 years, many of those years on lithium cells, and has also assisted or installed lithium cells on 24 other boats used by full time live-aboard cruisers, with cells that have reached their end of life. These lasted between 6 to 15 years, with the shorter life being cells of a lower cycle rating and the longer range for cells that had a very high cycle rating. While this is not a highly precise result, and such should not be expected as precise use of batteries will vary from user to user. But it does give an approximate sense of calendar life in comparison to cycle rating.

Cell Cycle Rating & Calendar Life as function of loading

Cell Cycle Rating - Based on Standard ESS of 0.5C charge and discharge to 80% DoD, and 80% residual capacity.

CDR = Usage is most typically at a Charge and Discharge range, shown.

_________________________________________________________________________________________

Do Lithium Cells of Other Chemistries from LiFePO4 Have Better or Worse Cycle and Calendar Life?

In short they have a much shorter cycle and calendar life. Most notably cells of Lithium Cobalt Oxide (LCO), Lithium Manganese Cobalt Nickel (NMC), and Lithium Nickel Cobalt Aluminum (NCA) chemistries are typically cycle rated at 1000 to 2000 cycles, with a calendar life of 2 to 3 years. While these chemistries have a higher energy density and thus a smaller battery pack, they have shorter life and higher safety risk due to potential for autoignition. That potential doesn’t exist for LFP (lithium iron phosphate).

PART 6 - MAKING A WISE DECISION

If Battery Label or Website Claimed Cycle Rating is Not Reliable, How do I Make a Smart Decision?

That is a difficult question as the on-line influencers doing battery teardowns don’t explore this area. By not addressing the true cell cycle rating and thus the relative battery life, they are equating all lithium cells. As a battery manufacturer, when we place an order for 500 batteries made to our specs from a high-quality manufacturer, we specify many critical parameters including the cell quality we want them to use, namely the cell cycle rating per standard GB/T 31484-2015. If we ask for the price of a battery made with cheaper 2000 cycle Grade A cells, the battery cost to us is ½ that of the price for a battery of a true 4000 cycle rated cells. As our product objective is to have exceptional quality and longer life batteries, we usually specify cell rating of 6000 to 8000 cycles, and thus the cost to us is higher for these longer life cells, as is the resulting battery.

To have confidence in the quality of the battery you are buying, we suggest:

(1) Buy from a US battery manufacturer. We do the hard work of checking the actual quality we are receiving, with QC inspectors we send to the plant, before packaging and shipment. We don’t deal with the small-time shops that sell for low costs on Amazon or Temu. We also obtain cell manufacturer specs so our QC inspectors that visit the plant and our in-house techs check batteries before shipment and again on arrival in our warehouse against that spec.

(2) It is not practical for US marine or RV manufacturers or dealers to do the legwork to: engage local QC inspection services for batteries manufactured in China, perform in-house testing of samples and finished products, and obtain proper copies of cell manufacturer specs, it is better to rely on a US battery manufacturer to do that work.

(3) Ask for the cell manufacturer’s specification (10 - 20 pages), and confirm the cell cycle rating, if you can get it.

(4) Recognize that the supposed deals on Temu or Amazon are not really deals. With a low-cost battery, you are getting a shorter life battery than if you purchased a battery with high quality cells.

___________________________________________________________

[1] “Cycle Life Studies of Lithium-ion Power Batteries for Electric Vehicles: A Review,” July 15, 2024, Journal of Energy Storage, J. Zhang, Huang, G, Zhang, Dai b, Wen, Jiang

[2] “Comprehensive Review of Energy Storage Systems Technologies, Objectives, Challenges, and Future Trends,” July 2024, Energy Strategies Reviews, by Elalfy, Gouda, Kotb, Bures, Sedhom.

[3] “Aging Behavior of LiFePO4-Based Battery Cells at Stack Level: A Second-Life Cycling Study”, September 1, 2025, Journal of Energy Storage, by Aeppli, Hack and Held.

[4] “Research on Calendar Aging of Lithium-ion Batteries Used in Uninterruptible Power Supply System Based on Particle Filtering,” August 8, 2023, World Electric Vehicle Journal, by Wei Xu and Hongzhi Tan.

EXAMPLES:

Cell Specification cover page from EVE and Range of Cell Sizes from Topband, that only sells to the largest battery manufacturers.

Example latest technology, computer controlled slitting machine.