From the Blue Heron Tech Support Team - These observations came from multiple installers doing installations of Blue Heron lithium batteries, and were brought to the attention of the Blue Heron Tech Support Staff. The issues do not relate to lithium batteries, but are valuable findings to contribute to improved electrical safety in boats and yachts. They all represent close-calls or precursors to having a fire. And, all are things we suggest you pay attention to on your boat.

Summary

Several of our dealers and installers have relayed to us a number of instances of finding loose or corroded electrical connections and close calls on having a fire. We wanted to share this with our friends and clients. We suggest taking a look at your boat, and if you can, engage an ABYC installer to check for these conditions. Fix these before you have a fire from similar issues.

Findings

This paper summarizes several example cases of close calls on having a fire aboard a boat. These conditions could very well have occurred on an RV, so the lessons learned should be taken to heart on such vehicles as well. A common thread to these conditions is that most relate to connection integrity (loose connections or ones with corrosion) and the potential for that leading to overheating of wire. It is important to recognize the serious nature of such conditions, and to have them repaired as soon as possible.

Case 1- Battery Connection Issues (3 examples)

In three cases installers or dealers found the house battery bank to be inadequately secured. The AGM or flooded batteries had been allowed to move around as the sailboat heeled and bobbed, driving through waves. This continual motion in boats that travel a few thousand miles in a season offshore and in big seas, caused several battery cable connections to become loose to extremely loose. On one boat, as the connection was the primary positive connection to the full battery bank, the loose connection caused a severe charring of the cable insulation and the cable had to be replaced. The other two had only moderate to no discoloration, but perhaps that would have progressed in time. In the case of the first boat, the owner acknowledged to the installer he thought he smelled smoke from time to time, but could never locate the source.

Whether batteries are lead acid or lithium, it is important that the batteries be well secured. Our preference is to have batteries secured to not permit any noticeable movement if one pushed the battery, whether it is lead acid or lithium.

Recommendation – Check that batteries are secured and that movement is restricted. Check all DC battery cable connections at the battery and at shunts, bus bars, posts, engine, generator, inverters, windlass, winches, bow thruster, circuit breakers and battery/inverter switches. At the batteries it is acceptable to grab cables by hand and confirm they are not loose. (Do not do that with AC cables or wiring; leave that for an expert if unsure.) It would be a good idea to have a technician go over the boat to check these connections and method of securing batteries.

Case 2 – AC Wiring Connection

A boat owner, while running a generator at anchor to power two battery chargers, well within the capability of the generator, began smelling smoke. As a retired pilot and trained fighter pilot, his reaction was to move quickly and he immediately switched off all loads and shutdown the generator. And then he began investigating the source of the smoke. While he had performed that battery bank charging function numerous times without smelling any smoke, he correctly didn’t let that cloud his judgement, and the need to stop the generator.

On checking surface temperatures of buses, junction boxes, and electrical equipment, he found one AC junction box and wires exiting that box to be very hot, and noticed some wisps of smoke coming from that junction box. On carefully opening the box after assuring himself there was no active fire in the box, he found the insulation on many of the wires in the box to be charred and heavily damaged, and had been apparently close to igniting. The box contained the main 120VAC power cable from the generator, feeding a busbar in the box, with several wires apparently feeding loads. He immediately noted two problems: (1) the ring terminal for the major cable/wire from the generator (L1) was extremely loose, and (2) there were no fuses or circuit breakers for the branch lines coming from the junction box. The generator was a new installation done by a reputable catamaran yard in Florida. The junction box should have been a breaker panel with individual breakers for each of the branch circuits; the installer had at least added a circuit breaker at the generator in the line feeding the junction box. The immediate close-call that nearly led to a fire was the loose connection on the feed from the generator to the bus feeding the branch circuits. The installer had failed to adequately torque the bolt on the bus bar. The quick action by the owner avoided a serious fire.

Recommendation – Be careful checking for loose connections on 120VAC lines. This may be best for an ABYC electrical technician to check across your boat. When doing charging operations, note any elevated temperatures of junction boxes. Use a thermal (IR) monitoring device to check the temperature of 120VAC junction boxes and high current connections, such as on busbars, breakers, charger connections, water heater connections, shore power plugs and circuit breakers, and air conditioning junction boxes.

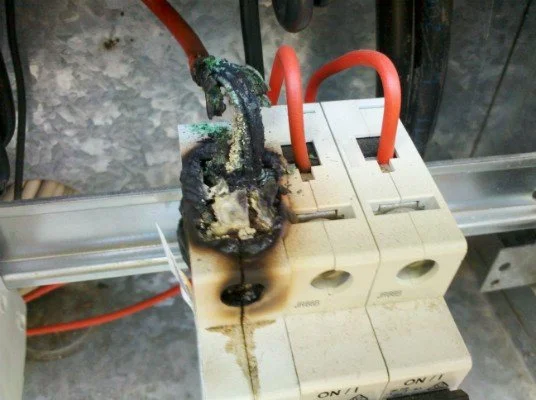

Case 3 – Corrosion (2 examples)

On two other boats, installers found evidence of some wiring insulation damage at busbars or electrical connections. These connections also showed evidence of some corrosion. Corrosion is another means of interfering with the electrical connection and causing a high electrical resistance at the connection. The current needed for the equipment is forced to pass through a small cross section of metal where there is still some electrical connection around the corrosion. This high current in a high resistance path leads to overheating, and can lead to igniting the wiring insulation, resulting in a serious fire. Fuses do not prevent this type of problem leading to a fire.

Corrosion has no business at electrical connections. A good survey usually looks for this, but sometimes these problems are under covers and not obvious to the screening type of survey usually done on boats. In these two cases, after finding a few examples, the installers broadened their survey and found other examples. This was a secondary benefit of doing a lithium upgrade using knowledgeable electrical technicians.

Recommendation – Take the time to look at all the electrical connections you can put your eyes on, opening all lockers. Particularly look at DC and AC busbar, circuit breaker, alternator, battery charger, inverter, and generator connections. Ask your installer to do a thorough inspection of electrical connections.

FEEDBACK FROM ABYC TECHNICIANS

April 14, 2023